Posted by Nicky Smol on March 25, 2024 in Product information

PVC Signage is signage made of PVC. Polyvinyl Chloride (PVC) plastic, commonly known as “vinyl,” has become one of the most widely used types of plastics. Its advantages are that it is highly versatile and relatively inexpensive. PVC is also widely used when it comes to signage all over the world. However, when it comes to safety signage, there are a lot of raising concerns to using PVC.

The PVC lifecycle (production, use, disposal) results in the release of toxic chlorine-based chemicals. These toxins are building up in the water, air, and food chain.

Although PVC is flame resistant, PVC products release toxic hydrogen chloride gas when heated. In the unfortunate case of a fire, these toxins will be released and can be dangerous for firefighters, crew, and passengers, where these corrosive gases can spread faster than flames, trapping occupants before they have a chance to escape. Hydrogen chloride gas is even lethal when inhaled and, according to fire experts, it is not unusual for people caught in building fires to be killed by toxic PVC fumes before the flames reach them.

The safety of shipping is an increasingly pressing concern, with the causes of maritime casualties being manifold. Among these, fires on ships stand out as particularly hazardous incidents, frequently resulting in significant damage and accidents. Recognizing these risks, ship safety regulations advocate for the use of materials that exhibit low fire propagation, are resistant to fire, and produce minimal smoke emissions and are free from halogens.

Chapter 11-2 of SOLAS focuses on mitigating the risks associated with fires, including the prevention of fires and explosions, the potential for smoke generation, and toxicity. The objective of this regulation is to minimize the threats posed by smoke and toxic substances produced during a fire. Certain materials become toxic when they burn, posing significant dangers to individuals on board a vessel. As a result, it’s crucial to control the amount of smoke and toxic emissions from flammable materials.

Despite these stringent criteria, the use of potentially hazardous materials such as PVC is still permitted. It is therefor important to explore the risks associated with using PVC signs compared to Low Smoke Zero Halogen (LSOH) signs, like PETx, especially concerning equipment safety and personnel in the event of a fire.

At the same time, we see the maritime sector is gradually shifting away from the use of halogen-containing products, like PVC, as part of its effort to decarbonize. Although the contribution of PVC-free products to this goal may seem minor compared to the overall emissions from ships, it is still a significant step towards the decarbonization of fleets. A study of 165 fires aboard the DNV fleet from 1992 to 1997 showed that engine room fires were the most common, making up nearly two-thirds of all incidents, with significant risks also coming from fires in cargo spaces and living areas. These risks are increased by the use of flammable materials like PVC, which, despite being flame-resistant, can produce dangerous smoke, toxic hazards, and corrosive damage when burned.

PVC’s combustion, especially when water is used to extinguish the fire, releases harmful hydrochloric acid vapor, leading to further damage. Research indicates that PVC ignites more quickly and produces more smoke and toxicity compared to low-emission materials like polyethylene. In contrast, PET materials emit significantly fewer toxic gases, such as CO and HCl, reducing the risk of intoxication and minimizing corrosive damage to electronics. The early stages of a fire, where PVC poses the greatest risk of emitting toxic gases and smoke, are particularly dangerous.

To enhance onboard safety, the maritime industry has adopted halogen-free, low-smoke, and non-toxic materials like those used in SafeSign Petx signs and low-location lighting. This shift, initiated by T-ISS in collaboration with DNV in 2010, represents a critical advancement in improving fire safety and overall ship safety protocols, underscoring the industry’s commitment to fire prevention and effective response measures.

PET-X is a type of polyester plastic known for its clarity, strength and recyclability. PET-X is a modified PET, which stands for Polyethylene Terephthalate. This material offers a combination of visual appeal, durability, and environmental sustainability, making it a preferred choice for a wide range of applications, especially for safety signs.

SafeSign (Powered by T-ISS) innovated the sign industry by replacing the commonly used PVC with PETX. PVC contains halogens, which can produce highly toxic fumes, and therefore the use of PVC is more and more prohibited. Another benefit of PETX used, is the resistance against UV. Where PVC will discolor, and becomes yellowish, SafeSign PETX comes with a 5 year warrantee, even when used outdoor. SafeSign signs will not discolor.

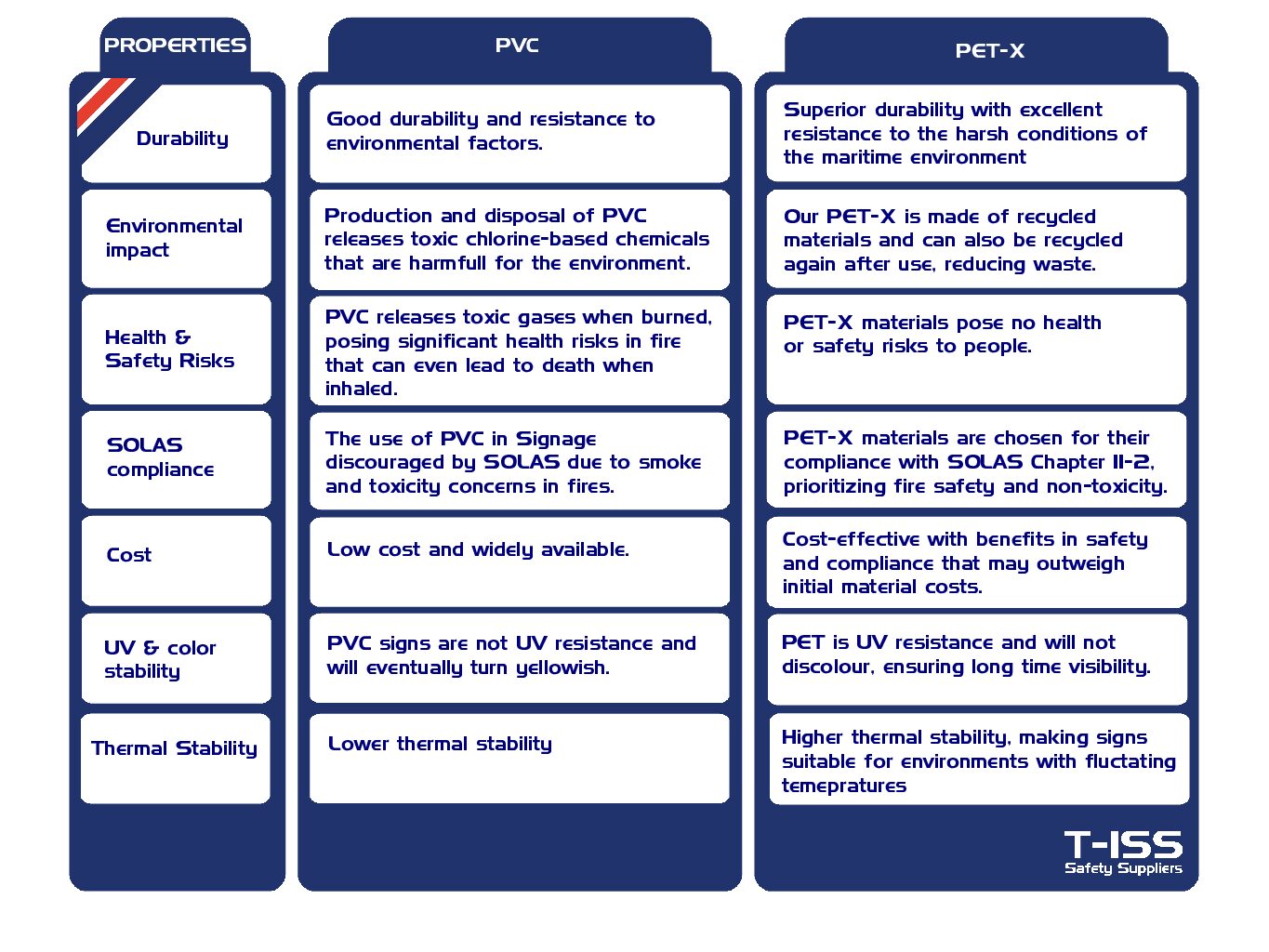

PET-X signage offers several advantages over PVC signage, particularly in the context of environmental impact, safety, and compliance with regulations like SOLAS Chapter 11-2, which focuses on fire safety and reducing hazards from smoke and toxic products. Here are some key benefits of PET-X compared to PVC signage:

The photoluminescent material used on SafeSign PET-X signs, stores the energy from light sources and releases the light energy in darkness. To activate the photoluminescent material the signs need a lightsource. The brightness and period of glow of signs depend on the grade and thickness of the pigment. SafeSigns only uses photoluminescent material that exceeds the glow properties required. All of our photoluminescent signs and Low Location Light systems use the same, DNV certified, material.

Are you interested in our products or in becoming one of our dealers? Please contact us for the possibilities by clicking here!