IMO SafeSign- The photo luminescent material used on SafeSign signs, stores the energy from light sources and releases the light energy in darkness. SafeSign only uses 100% environmentally friendly material, free from any toxics or radioactive additives. To activate the photoluminescent material the product needs light. The brightness and period of glow depends on the grade and thickness of the pigment. SafeSigns only uses photo luminescent material that exceeds the glow properties required. All photo luminescent signs and Low Location Light systems use the same, DNV certified, material.

SafeSign innovated the sign industry by replacing the commonly used PVC with a modified PET, called PETX. The benefit of this PETX is that the product is completely recyclable, reducing the environmental footprint. PVC contains halogens, which can produce highly toxic fumes, and therefore the use of PVC is more and more prohibited. Another benefit of PETX used, is the resistance against UV. Where PVC will discolor, and becomes yellowish, SafeSign PETX comes with a 10 year warrantee, even when used outdoor. SafeSign signs will not discolor.

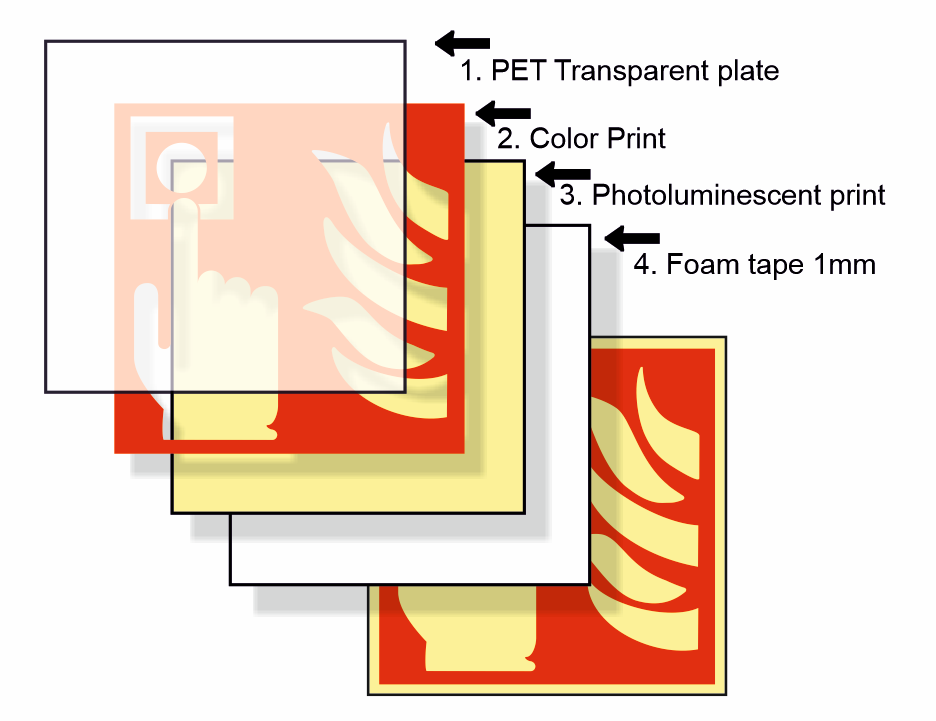

SafeSign innovates by introducing a new way of sign printing. Instead of printing the photo luminescent layer and color print from the front, we developed a procedure whereby the colors are printed from the backside. After this we print the photoluminescent layer. This way, we protect the printing from environmental influences. From the back side the sign we seal the sign with a PE closed-cell foam tape. This has a self-adhesive backing which you can use to fix the product to a surface. The result is a clear, high-quality sign with a glossy, shiny finish on the front. You can easily clean the sign and apply it to almost any surface due to the adhesive backing. We deliver all signs with a protective front film. You should remove this film after the sign is stuck to a surface.

The cost of signs will be a small part of your total signage expenses. Identicications, ordering, transport, installation and invoicing are usually more than 90% of the cost. You can reduce this substantially by using SafeSign signs. SafeSign signs will last a minimum of 10 years, guaranteed. The signs are easy-to-fix thanks to the selfadhesive backing. Save serious money on all these replacement cost while applying an evironmental friendly purchasing policy. Sustainability through innovation!

Solas Chapter 11-2 Reg 6 Part B 6.2 Part B – Prevention of Fire and Explosion Regulation 6 – Smoke Generation Potential and Toxicity

1. Purpose

The purpose of this regulation is to reduce the hazard to life from smoke and toxic products generated during a fire in spaces where persons normally work or live. For this purpose, the quantity of smoke and toxic released from combustible materials must be limited.

2. Paints, varnishes and other finishes

Paints, varnishes and other finishes used on exposed interior surfaces shall not be capable of producing excessive quantities of smoke and toxic products, this being determined in accordance with the Fire Test Procedures Code.

Solas Chapter 11-2 Reg 5 Part B 3.2.4.1

The following surfaces shall have low flame-spread characteristics in accordance with the Fire Test Procedures Code:

3.2.4.1 In passenger ships: 3.2.4.1.1 exposed surfaces in corridors and stairway enclosures and of bulkhead and ceiling linings in accommodation and service spaces (except saunas) and control stations, etc.

SafeSign is the only manufacturer who supplies all signs, posters and LLL-strips with a selfadhesive backing. You will never have to use adhesives or other methods for fixing. We specifically selected the selfadhesive backing, from a PE closed-cell foam, to withstand the harsh marine environment. We deliver all signs, posters and LLL strips, with a protecting front film. You should remove this film after you’ve applied the product.

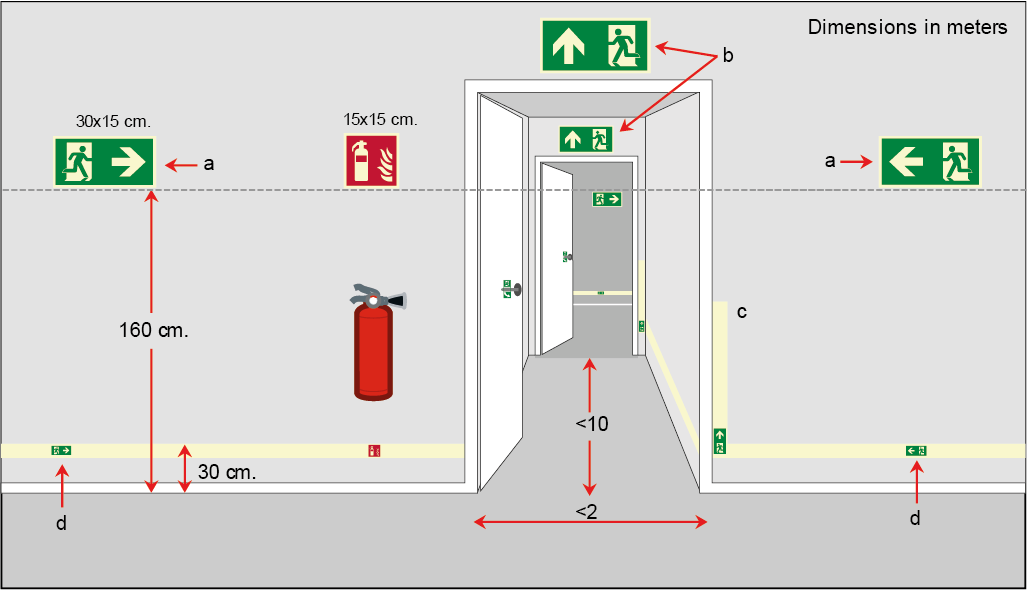

This illustration depicts an example of components used to convey one of the several possible layouts of a

safety way guidance system for a typical detail of escape route:

a: Escape route sign at intermediate position

b: High mounted single-sided photo illuminated safety sign

c: Indicator of the frame and door handle

d: Guidance line with directional indicator

The example is based on ISO 16069 Safety Way Guidance System

Our new signs will comply with the ISO 24409 standard. This will mean that some of our signs are replaced by newer ones. On the left you can see which signs will be replaced, and which signs you should use to comply with the all-new ISO 24409 regulations. If you have any questions regarding this new regulation, please contact us.

All photo luminescent signage needs to meet the requirements stated in IMO resolution 752(18). This means that these signs need to provide, as a minimum, 15 mcd/m2 after 10 minutes and 2 mcd/m2 after 60 minutes when no longer exposed to an illuminating source. You need to test the luminance of signs, as low location light systems, at least once every 5 years. Therefore it’s key to use quality signs which provide these values, and not only in the first months.

Especially signs used outside need to be of such a quality that the exposure to UV does not discolour the plastic. You won’t meet the requirements when this is the case. We make T-ISS signs from PETX. This modified polymer plastic won’t discolour when it’s exposed to UV light. We protect the photoluminescent layer by printing the signs from the backside. You can rest assure, when using our signs, that you’ll be safe for at least 10 years.

According to Solas regulations, you have to place information signs in the direct area of rescue and lifesaving devices. The signs must explain function, control and actions to be taken. SafeSign designs for this training and instruction posters which come in a outdoor high quality self adhesive PETX. The size is in general 30×40 cm. On special request we supply these signs bi-lingual. If you have any questions or special requests please don’t hesitate to contact us.